- M :- +91 966 423 0207

- E :- salimexport.in@gmail.com

-

DN 15, 20, 32, 40, 50, 65, 80, 100 suitable for installation between PN 6, 10, 16, 25,40

Available with IBR All certification/inspection requirement must be stated at the time of order placement.

Designed and manufactured in accordance with BS 7438

Heavy duty springs 700 m bar opening pressure up to DN 50 forboiler feed applications.

Viton soft seats for oil, gas and steam applicationsEPDM soft seats for water applications.

| No | Part | Material | Standard |

|---|---|---|---|

| 1 | Body | Austentic stainless steel | ASTM A 351 CF8M |

| 2 | Disc | Austentic stainless steel | ASTM A 351 CF3M |

| 3 | Spring retainer | Austentic stainless steel | ASTM A 240 SS2316L |

| 4 | Standard spring | Austentic stainless steel | IS4454:IV:GR, 3 SS316 |

| Body design conditions | PN 40 | ||

| PMO- Maximum operating pressure | 40 bar g | ||

| TMO- | |||

| Maximum | Standard Spring | 300°C | |

| Operating | Heavy duty spring | 300°C | |

| Temperature | Without spring | 400°C | |

| Minimum operating temperature (standard disc) | -10°C | ||

| Temperature | |||

| Vition Seat | -10°C to +250°C | ||

| EPDM Seat | -10°C to +150°C | ||

| Maximum cold hydraulic test pressure | 80 bar g | ||

Standard valves conform to DIN 3230 part 3, BN2 Valves conforming to DIN 3230 part 3, BO3 available on request.

Soft seated versions meet DIN3230 part 3 BN1 and BO1 provided a differential pressure exists.

Forbes Marshall spring-loaded disc check valves are opened by the pressure of the fluid and closed by the spring as soon as flow ceases and before the reverse flow occurs,

| SIZE | A | B | C | D | E | F | G | Weight |

|---|---|---|---|---|---|---|---|---|

| DN15 | 60.0 | 45 | 43 | 38 | 16.0 | 29.0 | 15 | 0.13 |

| DN20 | 69.5 | 55 | 53 | 45 | 19.0 | 35.7 | 20 | 0.19 |

| DN25 | 80.5 | 65 | 63 | 55 | 22.0 | 44.0 | 25 | 0.32 |

| DN32 | 84 | 78 | 75 | 68 | 28.0 | 54.5 | 32 | 0.53 |

| DN40 | 101.0 | 88 | 85 | 79 | 31.5 | 65.5 | 40 | 0.74 |

| DN50 | 115.0 | 98 | 95 | 93 | 40.0 | 77.0 | 50 | 1.25 |

| DN65 | 129 | 118 | 115 | 113 | 46.0 | 97.5 | 65 | 1.84 |

| DN80 | 154 | 134 | 133 | 128 | 50 | 111.5 | 80 | 2.42 |

| DN100 | 184 | 154 | 154 | 148 | 60 | 130 | 100 | 3.81 |

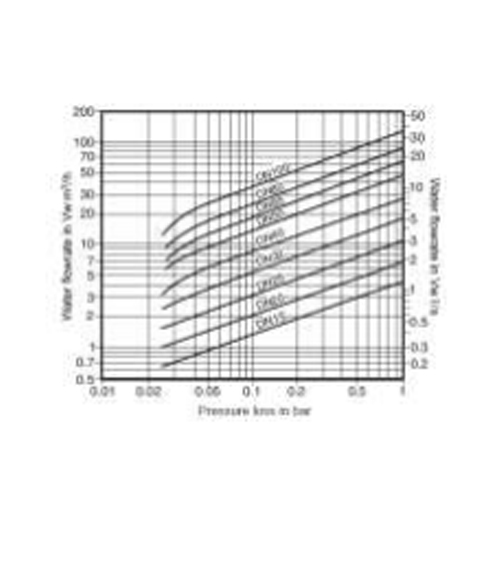

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| Kv | 4.4 | 6.8 | 10.8 | 17 | 26 | 43 | 60 | 80 | 113 |

| For conversion : Cv (UK)=Kv x 0.963 Cv(US)=kv x 1.158 | |||||||||

Differential pressures with zero flow for standard and high temperature springs.

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| up | 24 | 24 | 24 | 24 | 27 | 29 | 29 | 30 | 30 |

| right | 22 | 22 | 22 | 22 | 23 | 25 | 25 | 25 | 25 |

| Down | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 19 |

| Where lowest opening pressures are required, valves without springs can be installed in vertical pipes with bottom-to-top flow without spring | |||||||||

| up | 2.5 | 2.5 | 3 3 | 4,0 | 4,5 | 4.5 | 5 | 6 | |

| Heavy duty springs approximately 700 mbar | |||||||||

Where lowest opening pressures are required, valves without springs can be installed in vertical pipes with bottom-to-top flow without spring

Safety Information, Installation and Maintenance

For full details see the user manual supplied with the product. FMDCV spring loaded disc check valves must be fitted in accordance with the indicating correct fluid flow direction. When fitted with a spring they can be installed in any plane. When supplied without a spring they must be fitted in a vertical flow line with the flow from bottom-to-top.

The 'cam' design of the body allows the various flange types to be accommodated. The body is rotated to touch the flange joint bolts ensuring that the valve is centered in the pipeline.

Note: Flanges, bolts (or studs), nuts and joint gaskets are to be provided by the installer. Forbes Marshall spring loaded disc check valves are non- maintainable (no spares are available) and are not suitable for use where heavily pulsating flow exists, such as close to a compressor.