- M :- +91 966 423 0207

- E :- salimexport.in@gmail.com

-

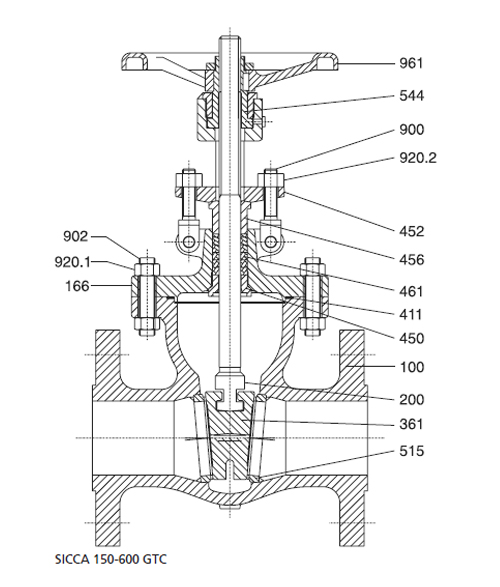

KSB gate valves are highly effective and undergo numerous rigorous tests before being supplied to the final consumer. Gate valves have a long lifespan. It lowers business maintenance costs, which immediately results in high-quality output. They can be used in various applications because of their ability to withstand a range of pressure ratings. Worldwide, there is a great need for KSB gate valves..

| Class | Material | [°F] | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| -20 to +100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 | 1400 | 1450 | 1500 | ||

| 150 | A216 WCB 1) | 285 | 260 | 230 | 200 | 170 | 140 | 125 | 110 | 95 | 80 | 65 | 50 | 35 | 20 | - | - | - | - | - | - | - | - | - | - |

| 300 | 740 | 680 | 655 | 635 | 605 | 570 | 550 | 530 | 505 | 410 | 320 | 230 | 135 | 85 | - | - | - | - | - | - | - | - | - | - | |

| 600 | 1480 | 1360 | 1310 | 1265 | 1205 | 1135 | 1100 | 1060 | 1015 | 825 | 640 | 460 | 275 | 170 | - | - | - | - | - | - | - | - | - | - | |

| 150 | A217 WC62)3) | 290 | 260 | 230 | 200 | 170 | 140 | 125 | 110 | 95 | 80 | 65 | 50 | 35 | 20 | 20 | 20 | 20 | 15 | - | - | - | - | - | - |

| 300 | 750 | 750 | 720 | 695 | 665 | 605 | 590 | 570 | 530 | 510 | 485 | 450 | 320 | 215 | 145 | 95 | 65 | 40 | - | - | - | - | - | - | |

| 600 | 1500 | 1500 | 1445 | 1385 | 1330 | 1210 | 1175 | 1135 | 1065 | 1015 | 975 | 900 | 640 | 430 | 290 | 190 | 130 | 80 | - | - | - | - | - | - | |

| 150 | A351 CF84) | 275 | 230 | 205 | 190 | 170 | 140 | 125 | 110 | 95 | 80 | 65 | 50 | 35 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 15 |

| 300 | 720 | 600 | 540 | 495 | 465 | 440 | 430 | 420 | 415 | 405 | 395 | 390 | 380 | 355 | 325 | 255 | 205 | 165 | 135 | 115 | 95 | 75 | 60 | 40 | |

| 600 | 1440 | 1200 | 1075 | 995 | 930 | 885 | 865 | 845 | 825 | 810 | 790 | 780 | 765 | 710 | 650 | 515 | 410 | 330 | 265 | 225 | 185 | 150 | 115 | 85 | |

| 150 | A351 CF8M4) | 275 | 235 | 215 | 195 | 170 | 140 | 125 | 110 | 95 | 80 | 65 | 50 | 35 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 15 |

| 300 | 720 | 620 | 560 | 515 | 480 | 450 | 440 | 435 | 425 | 420 | 420 | 415 | 385 | 365 | 360 | 305 | 235 | 185 | 145 | 115 | 95 | 75 | 60 | 40 | |

| 600 | 1440 | 1240 | 1120 | 1025 | 955 | 900 | 885 | 870 | 855 | 845 | 835 | 830 | 775 | 725 | 720 | 610 | 475 | 370 | 295 | 235 | 190 | 150 | 115 | 85 | |

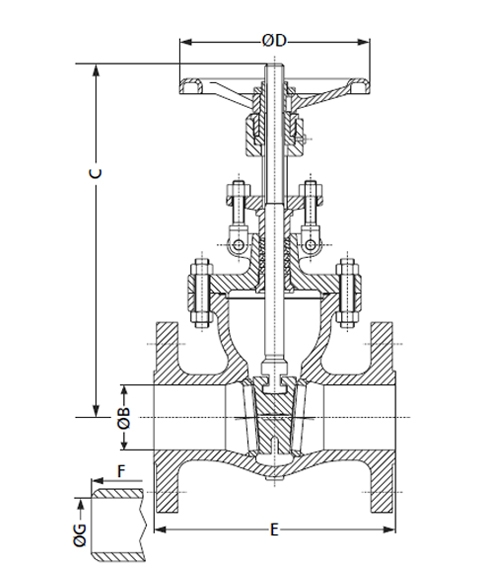

| Class | NPS | ØB | C8)9) | ØD | E | F10) | ØG10) | With flanged ends | With butt weld ends |

|---|---|---|---|---|---|---|---|---|---|

| [inch] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg]9) | [kg]9) | |

| 150 | 2 | 51,0 | 370,0 | 203,0 | 177,8 | 215,9 | 52,5 | 15,0 | 12,0 |

| 2 1/2 | 62,5 | 423,0 | 254,0 | 190,0 | 241,0 | 62,5 | 25,0 | 20,0 | |

| 3 | 76,0 | 445,0 | 254,0 | 203,2 | 282,5 | 78,0 | 25,0 | 22,0 | |

| 4 | 102,0 | 530,0 | 254,0 | 228,6 | 304,8 | 102,0 | 40,0 | 35,0 | |

| 5 | 128,0 | 705,0 | 356,0 | 254,0 | 381,0 | 128,0 | 60,0 | 55,0 | |

| 6 | 152,0 | 720,0 | 356,0 | 266,7 | 403,4 | 154,0 | 70,0 | 65,0 | |

| 8 | 203,0 | 1021,0 | 356,0 | 292,1 | 419,1 | 203,0 | 125,0 | 112,0 | |

| 10 | 254,0 | 1235,0 | 457,0 | 330,2 | 457,2 | 254,5 | 200,0 | 180,0 | |

| 12 | 305,0 | 1444,0 | 508,0 | 355,6 | 501,7 | 303,0 | 280,0 | 245,0 | |

| 14 | 336,0 | 1665,0 | 508,0 | 381,0 | 572,0 | 333,5 | 425,0 | 405,0 | |

| 16 | 387,0 | 1910,0 | 610,0 | 406,4 | 609,6 | 381,0 | 550,0 | 555,0 | |

| 18 | 438,0 | 2050,0 | 700,0 | 431,8 | 660,4 | 428,5 | 675,0 | 680,0 | |

| 20 | 489,0 | 2275,0 | 800,0 | 457,2 | 711,2 | 478,0 | 815,0 | 820,0 | |

| 24 | 591,0 | 2680,0 | 900,0 | 508,0 | 812,8 | 574,5 | 1220,0 | 1220,0 | |

| 300 | 2 | 51,0 | 410,0 | 203,0 | 215,9 | 215,9 | 52,5 | 28,0 | 25,0 |

| 2 1/2 | 62,5 | 452,0 | 254,0 | 241,0 | 241,0 | 62,5 | 40,0 | 30,0 | |

| 3 | 76,0 | 505,0 | 254,0 | 282,5 | 282,5 | 78,0 | 45,0 | 40,0 |