- M :- +91 966 423 0207

- E :- salimexport.in@gmail.com

-

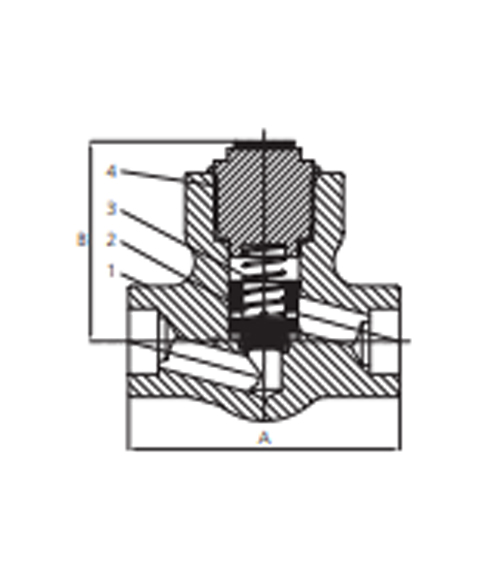

L&T make forged check valve have a lift type check valve mechanism which stop application from flowing back and. L&T check valve helps reduce the danger of leakage and face the harsh conditions and works phenomenally with low maintenance. L&T check valve increase the life of plant decrease maintenance cost increase immense profit of company.

| Size | Class 1500/ 2500 | Class 4500 | |||||

|---|---|---|---|---|---|---|---|

| NPS | DN | A | B | Wt. | A | B | Wt. |

| ½ | 15 | 115 | 83 | 3 | 130 | 77 | 5 |

| ¾ | 20 | 115 | 83 | 3 | 130 | 77 | 5 |

| 1 | 25 | 130 | 92 | 5 | 165 | 97 | 9 |

| 1¼ | 32 | 178 | 122 | 9 | 188 | 127 | 18 |

| 1½ | 40 | 178 | 122 | 9 | 188 | 127 | 18 |

| 2 | 50 | 202 | 136 | 14 | 230 | 146 | 30 |

| All dimensions in mm and weights in kgValves in ASME Classes 1500 & 2500 are available in sizes up to 2” | |||||||

| No. | Components | Materials | |||

|---|---|---|---|---|---|

| A105 | F22 | F91 | F304 | ||

| 1 | Body (Integral Seat) | A105 | A182 Gr. F22 Cl. 3 | A182 Gr. F91 | A182 Gr. F304 |

| 2 | Disc | A479 Type 410 + HF | A479 Type 410 + HF | A479 Type 316 + HF | A479 Type 316 + HF |

| 3 | Spring | Inconel X750 | |||

| 4 | Cover | A105 | A182 Gr. F22 Cl. 3 | A182 Gr. F91 | A182 Gr. F304 |

| -- | Identification Plate | Stainless Steel | |||

| HF - Hard-Faced with Stellite 6 or equivalent | |||||