- M :- +91 966 423 0207

- E :- salimexport.in@gmail.com

-

A three-piece ball valve offers several advantages over other valve types due to its unique design and construction. Here's a breakdown of its typical uses:

High-pressure, high-cycle applications: The three-piece design allows for easy disassembly and replacement of worn components

Oil and gas pipelines

Chemical processing plants

Power generation facilities

Applications requiring frequent cleaning or maintenance: The ability to disassemble the valve simplifies cleaning and maintenance without removing it from the pipeline, minimizing downtime and costs.

Full-Port Design: Allows for unrestricted flow with minimal pressure drop, improving efficiency.

Bi-Directional Flow : Can handle flow in either direction without affecting performance.

Leak-Proof Operation : Tight sealing ensures minimal leakage, even in demanding applications.

Durability : Robust construction materials and design contribute to long service life.

Max. Cold Working Pressure : 69kg/cm2 for screwed/socketweld end valves with PTFE seat 103kg/cm2 for screwed/socketweld end valves with polyfill seat As per flange rating for flanged valves

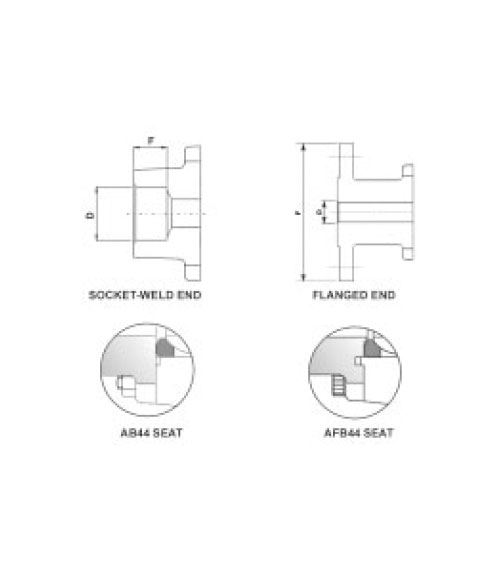

Valve Design : BS 5159 for A44 Series / BS 5351 for AF44 Series

Fire Test (for AFB44) : API 607 4th edition

Testing : API 598 for flanged valves

Face-To-Face Dimensions : ASME B16.10 for flanged valves and AIL Standard for screwed/socket-weld end

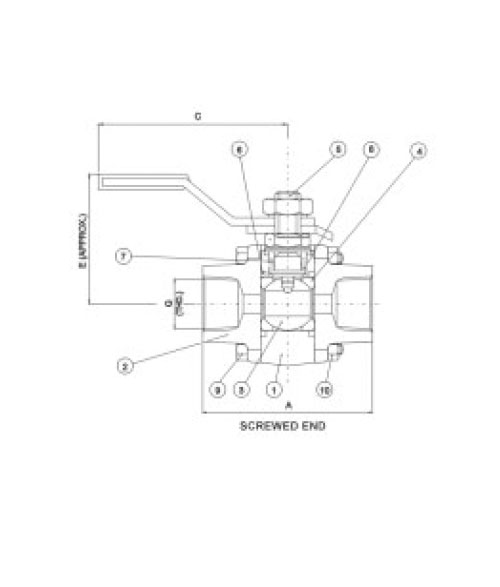

| Valve Size | A | C | D | E | F | G | Approx. Weight (kg) |

|---|---|---|---|---|---|---|---|

| 15 | 73 | 122 | 22.2 / 21.8 | 48 | 9.7 | 1/2” | 0.8 |

| 20 | 95 | 149 | 27.6 / 27.1 | 59 | 12.7 | 3/4” | 1.6 |

| 25 | 116 | 181 | 34.3 / 33.8 | 75 | 12.7 | 1” | 3.3 |

| 40 | 128 | 181 | 49.2 / 48.7 | 80 | 12.7 | 11/2” | 4.1 |

| Valve Size | C | D | E | Class 150 | Class 300 | Class 600 | Approx. Weight (kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | F | G | A | F | G | A | F | G | Cl. 150 | Cl. 300 | Cl. 600 | ||||

| 15 | 152 | 12.7 | 98 | 108 | 89 | 11.1 | 140 | 96 | 15 | 165 | 96 | 22 | 2.3 | 3.2 | 6.3 |

| 20 | 177 | 19.1 | 102 | 117 | 99 | 12.2 | 153 | 118 | 17 | 191 | 118 | 24 | 3.1 | 4.5 | 9.1 |

| 25 | 202 | 25.4 | 121 | 127 | 108 | 11.1 | 165 | 124 | 19 | 216 | 124 | 26 | 6.4 | 8.7 | 15.4 |

| 40 | 202 | 38.1 | 126 | 165 | 127 | 14.3 | 191 | 156 | 22 | 241 | 156 | 30 | 9.0 | 10.8 | 21.6 |

| Sl. No. | Part | Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel |

|---|---|---|---|---|---|

| 1 | Body & Body Connector | ASTM A105 or ASTM A216 Gr. WCB | ASTM A351 Gr. CF8M | ASTM A105 | ASTM A351 Gr. CF8M |

| 2 | Ball | ASTM A351 Gr. CF8M | ASTM A351 Gr. CF8M | ||

| 3 | Seat | PTFE | PTFE | ||

| 4 | Stem | AISI 316 | AISI 316 | ||

| 5 | Body Seal | PTFE | Graphite | ||

| 6 | Gland Packing | 35% Carbon-filled PTFE | Graphite | ||

| 7 | Stem Seal | 35% Carbon-filled PTFE | 35% Carbon-filled PTFE | ||